January 10, 2024

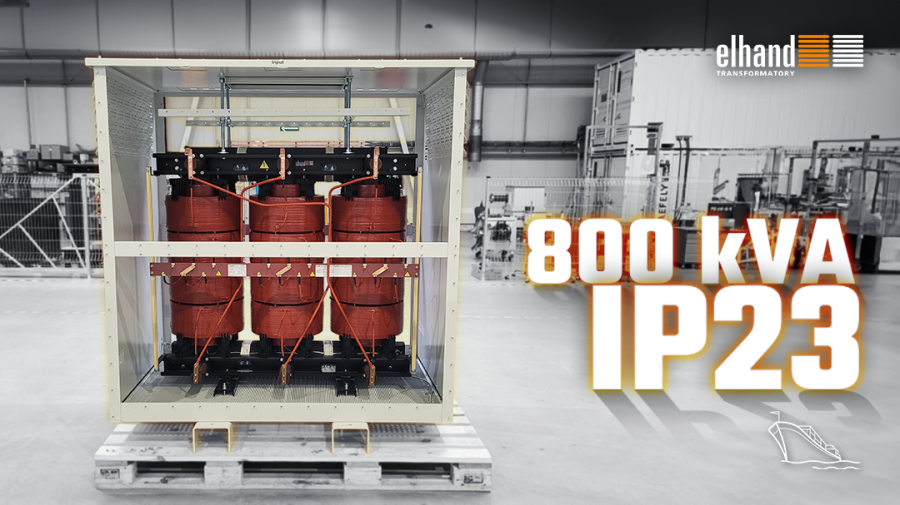

ELHAND Projects in Practice: Transformer MV 800kVA

#FromDesignToSolution: ELHAND Engineering Projects in Practice

Designing customized solutions is mutually beneficial for both the client and the designer ????. Our individual approach to each project allows us to create products that are perfectly tailored to the changing needs and expectations of our clients.

An example of this is a recent project, executed under the guidance of Adam Ptak, Key Account Manager.

The MV ET3HM transformer, designed for a dry dock shipyard measuring 128 meters in length and 30.5 meters in width and designed to overhaul ships with a deadweight capacity of up to 5,000 DWT and a design draft of 10 meters, is an excellent example of the ability to adapt to specific requirements.

Thanks to the unique design of the enclosure, created by Elhand's designers, we were able to tailor the cable lead-in and lead-out according to the customer's wishes.

The diameters of the holes for the cable glands were precisely matched to the types of cables, which enabled the customer to easily connect the transformer without having to make changes to the dock structure.

Timeliness of delivery was also key in the project, allowing the client to avoid the need to cut holes in the ship's hull and the associated additional costs.

For the designer, completing such a task is a chance to demonstrate design plasticity, which translates into a number of benefits, including for the client:

- It enables the creation of personalized solutions that exactly match the client's unique requirements .

- Fosters innovation and creative thinking .

- Provides the ability to adapt to new trends and continually evolve.

- Teaches how to deal effectively with unexpected challenges.

- Develops cooperation between different disciplines and specialists.

- Incorporates sustainability and ecological aspects into projects, which is increasingly important in today's world of industrial production.

Contact Adam and tell him about your needs > Adam Ptak | Key Account Manager